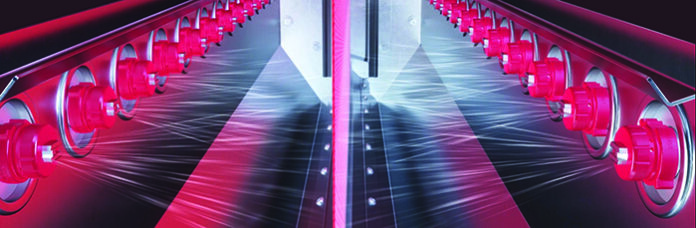

North Carolina State University’s Wilson College of Textiles has been making inroads challenging the conventional pad finishing process and significantly reducing its environmental footprint in collaboration with Baldwin Technology Inc. Front and center in its finishing lab is Baldwin’s TexCoat G4 digital finishing system.

For nearly 125 years, the Wilson College of Textiles at NC State University has been a hub of innovation and learning, transforming students into experts in the world of textiles. As the textile industry grapples with sustainability challenges, the college has embraced new technologies and innovations to address the issue head-on.

At the forefront of this transformation is the Zeis Textiles Extension for Economic Development, an arm of Wilson College that serves the textile industry’s prototyping and pilot production needs in its five laboratories – spun yarn, knitting, weaving, dyeing, and finishing, and physical testing. Collaborations with various textile companies have allowed the university to foster industry partnerships that bring forth groundbreaking ideas.

The partnership with Baldwin Technology marks a major milestone for the Raleigh, North Carolina-based college’s efforts to contribute to a more sustainable tomorrow.

“When a student comes into the school, one of the major things they ask is ‘What are we doing about sustainability?’” said Andre West, Director of the Zeis Textiles Extension at the Wilson College of Textiles at NC State. “As a university, we need to confront the idea that textiles have not been the most sustainable products out there.”

To tackle the longstanding challenges of unsustainable fashion, NC State has taken the lead in demonstrating to students and industry the transition from the traditional pad finishing process to Baldwin’s TexCoat G4 system. It offers an innovative “non-contact” precision spray that significantly reduces water consumption, energy usage, and chemical waste.

“Instead of needing to take the fabric, dip it into a bath to saturate it, squeeze the excess, dry and cure it, you can now precisely add the exact amount of finish you need on the fabric,” explained Rick Stanford, Baldwin’s VP Global Business Development of Textiles. “The TexCoat G4 system will reduce the amount of pick-up that’s required to carry the chemical onto the fabric. This will also take a lot less energy to dry the fabric, increasing production speeds.”

The adoption of the TexCoat G4 system signals a new era for the college, allowing students to actively participate in shaping a sustainable future for the textile industry. In the global effort to protect the planet and its resources, NC State’s Wilson College of Textiles is at the forefront, preparing the next generation of professionals to be the leaders of the sustainable textile movement.