Global diversified manufacturing leader Milliken & Company announced that it is the first textile manufacturer to offer non-PFAS materials for all three layers of firefighter turnout gear, including outer shell, thermal liner, and moisture barrier. Access to all three layers from a single U.S.-based supplier allows garment manufacturers to test the fabrics as a system while ensuring a complete chain of custody for the material — which can minimize delays and get gear into the hands of firefighters faster.

“Milliken is proud to be the only U.S. manufacturer offering non-PFAS fabric for every layer of turnout gear, but more importantly, we’re proud that these fabrics exceed performance standards,” said Marcio Manique, SVP of Protective Fabrics for Milliken. “Our team is passionate about helping to protect first responders, and our certification results prove that firefighters don’t have to compromise on health, protection, or comfort when choosing the right turnout gear.”

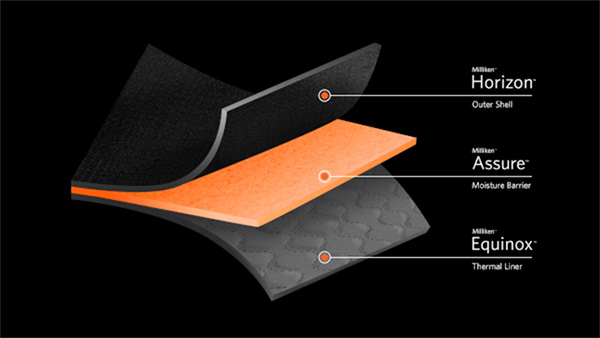

The three layers in the non-PFAS composites include:

- Milliken Horizon™: a non-PFAS, lightweight outer shell that provides industry-leading retention of strength and appearance year after year.

- Milliken Assure™: a non-PFAS, non-halogenated, flame-resistant moisture barrier that exceeds NFPA 1971-2018 requirements.

- Milliken Equinox™: a non-PFAS, slick thermal liner that offers superior wicking and moisture management, resulting in quick dry times and high levels of comfort and protection.

Third-Party Testing Results

The recently published NFPA 1970-2025 standard was issued with reduced performance criteria in anticipation of non-PFAS products having poorer performance; however, the Milliken composites were able to meet and exceed the more stringent NFPA 1971-2018 standard during the third-party testing process in November. Every individual layer that make up both composites are UL certified.

Detailed results from the third-party testing include:

- Composite 1: Horizon/Assure/Equinox 3-Layer

- Total Heat Loss (THL): 275

- Thermal Protective Performance (TPP): 40.9

- Composite 2: Horizon/Assure/Equinox 2-Layer

- Total Heat Loss (THL): 293

- Thermal Protective Performance (TPP): 38.2

NFPA requirements = THL: 205 (minimum) and TPP: 35 (minimum)

Massachusetts and Connecticut have already passed bans on the use of PFAS in firefighters’ protective equipment beginning as early as 2027. Milliken’s composites are the only high-performing, non-PFAS, non-halogenated FR options readily available on the market today. The company eliminated the use of PFAS chemistry from its fire service fabrics in 2021, and across its entire textile fibers and finishes portfolio in 2023.

These fabrics are available for use in wear trials now. For more information.