Nakagawa Chemical Inc. established the “cutting and pasting” culture in the industry with its Cutting Sheet (CS). The company was founded in 1975 as a spin-off from the New Materials Development Department of its predecessor, Nakagawado Co., Ltd., a sign manufacturing company. The company’s main business was the manufacture and sale of decorative sheets.

In addition to cutting sheets, the company now offers a lineup of “Foglas” frosted glass-like sheets, “Materio” decorative sheets made of real materials, as well as various inkjet media. The company also holds the “CS Design Award,” a design award, every two years as part of its efforts to raise awareness of the town’s aesthetics and good design.

The company has been utilizing inkjet printers for about 15 years for output and verification on its products. The company mainly outputs highly designed visuals such as artwork by famous artists and award-winning works.

In June 2022, the company introduced Mimaki Engineering’s latest eco-solvent printer, the JV330-160. We asked a Nakagawa Chemical representative how the printer was adopted and what it is like to use.

What kind of prints do you usually do?

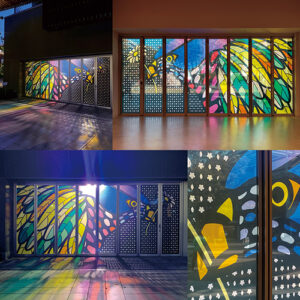

Shinshi: Since we are a sheet manufacturer, we do not usually print general advertisements or signs. We use inkjet printers as a means of expression in combination with our own products.

Hirano: For the exhibitions we hold at the CS Design Center, which is our showroom, it is important to showcase art and artwork in the best possible way. We design them by consulting with each other on which media to print and in what form to reproduce the artwork. In many cases, we print on our “C-001A” transparency film in the highest image quality mode.

How did you introduce “JV330”?

Shiina: Until recently, we had been using the “JV300.” It was a model with white ink, and it was very useful, but we wanted a multicolor model from the standpoint of reproducibility of works. After considering and examining various printers, including those from other companies, we decided to introduce Mimaki’s latest flagship model, the “JV330,” last June.

Saito: The deciding factor was that the 8-color machine, including orange and light black, produced very satisfactory colors. The body is solid and stable, and Mimaki’s RIP “RasterLink7” can be configured and adjusted in detail to produce the colors we want is also highly rated. The ability to share ink with the “JV300” was also a driving force behind the introduction of the JV330, as there is the hassle of storing and ordering ink inventory.

Six months have passed since the introduction.

Saito: It is really comfortable to be able to produce colors that could not be produced before. The level of color generation, color gamut, and saturation is so high that even a non-specialist can tell at a glance. I was not concerned about productivity before installing the printer, but the printing speed is very fast. When outputting the same or better quality than before, the finishing time has been reduced.

Shiina: Since its introduction, “JV330” has been working very well, and we have not called Mimaki’s technical support even once. Currently in the technical center, we operate by using “JV330” for prioritizing reproducibility and “JV300” when using white, differentiating their usage accordingly.

Future development of your business.

Shinshi: We are developing our business with a special focus on “design.” In order to expand the range of expression, we would like to explore the use of clear and white ink in the future. As companies, we are actively exploring what we can do in response to the growing necessity for environmental sustainability. We look forward to Mimaki continuing to listen to the opinions and requests of users like us, and to bringing even more innovative products to the market in the future.