Textile Machinery Manufacturers’ Association (India) at the “62nd Annual General Meeting of the Association” held on Friday, 30th September 2022 at 2.00 p.m. at “Lotus”, Hotel Trident, Nariman Point, Mumbai 400021.

Photo: TMMA

Respected Ms. Roop Rashi, Textile Commissioner-Mumbai, Ministry of Textiles, Mr. T. Rajkumar, Chairman, Confederation of Indian Textile Industry (Chairman-Sri Mahasakthi Mills Limited), my colleagues on the dais, distinguished guests and friends,

He extended a hearty welcome to all of you to the 62nd Annual General Meeting of Textile Machinery Manufacturers’ Association (India).

Photo: TMMA

He was grateful to Ms. Roop Rashi, Textile Commissioner-Mumbai, and Mr. T. Rajkumar, Chairman CITI, for accepting our invitation despite their busy schedule, as the Chief Guest and Guest of Honor respectively. He extended a warm welcome to both of them and would like to have their valuable advice and guidance to make the Textile Engineering Industry vibrant.

Before moving our Annual Report and the audited statement of accounts for approval of the members, He briefed about the Indian TEI in general and enumerate the role of the association in the year gone by.

The Year Gone By

It has been an absolutely prosperous year, especially after the bumpy ride of the

previous year.

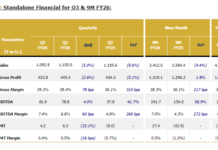

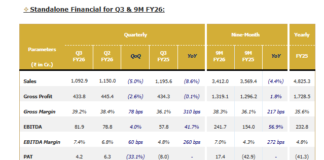

The fiscal year 2021-22 has shown one of the best growths of the entire textile and the textile machinery industry in the last few decades. A 130% production, 94% capacity utilization, 58% jump in exports and a 14% rise in the installed capacity that was stagnant for almost a decade; substantiates it all.

The year started on a gloomy note with the pandemic hovering our neighborhoods and compelling us to be grounded now and then.

It appeared that the renewed lockdown measures to contain mass population, industry and the institution from contracting the pandemic didn’t yield much result as there were mixed reactions from different quarters of the polity, community and decision makers globally on the issues of sustaining lives versus economies. While the developed countries including India were successful in developing the Covid-19 vaccine and initiating the mass vaccination programs, the rate of inoculating the populace proved insufficient. The coming quarters in the new fiscal year looked gloomy, but the industry proved all that wrong, as the entire value chain across the markets globally performed exceptionally well barring a few segments. The Government of India continued on the previous year’s strategies and action plans for business continuity, sectoral revival and further improving ‘Ease of Doing Business’ in the country.

Although the ongoing geopolitical tension has only aggravated the inflationary environment and trying to put brakes on the strong growth momentum, I am sure our Entrepreneurial spirits will continue to put up a fight and maintain our economy at full throttle.

Production-Export-Import Trends

The TEI scaled up its estimated annual installed capacity of Rs.12,500 crore per annum. The total provisional production of textile machinery, parts & accessories during 2021-22 recorded a substantial increase of 130% viz. Rs.11700 crore in 2021-22 as against Rs.5,095 crore achieved during 2020-21. Except the complete lockdown during Q1 of 2021-22 due to the disastrous second wave of Covid Pandemic, the majority of the industry segments continued on the momentum of the market gains picked up during 2nd, 3rd and 4th quarters of 2020-21quite well. Both greenfield and brown field projects were explored with clients during the Q2, Q3 & Q4 of the fiscal. Throughout the year, the capacity utilization was close to 100% and the industry was able to achieve up to 130% of their annual turnover as compared to 2020-21.

As per the data received from DGCI & S, the export of Indian TEI stood at Rs. 4291

crores in 2021-22 from Rs. 2721 crores in 2020-21. On the other hand, the import of

the Indian TEI stood at Rs. 12635 crores in 2021-22 as compared to Rs. 6778 crores

in 2020-21.

The total domestic demand for textile machinery during 2021-22, rose to Rs. 18,290

crores of which supplies from the domestic machinery industry amounted to

Rs.7,410 crore (minus exports), aggregating 41% of the total demand. The bulk of

the demand was met through imports.

Measures for Growth Orientation

Although the beginning of the year appeared a little bleak, the year 2021-22 ended

with a staggering US $400 Billion plus goods exports for the first time ever, thanks to Hon’ble Prime Minister’s vision of Make in India for the World and the Government’s deep engagement with the industry at all fronts.

The office of the textile commissioner coordinated and processed the ATUF Scheme efficiently, inspite of spending a few months of complete lockdown. Majority of the cases related to the enlistment of textile machine manufacturers, induction of new machine types in the ATUF scheme and the release of ATUF subsidy were cleared

on time. However, the uncertainty prevails in the industry about the lack of information on the continuation of ATUF Scheme after 31 st March 2022, when the scheme concluded.

The association worked closely with Kalam Institute of Health Technology (AMTZ

Vishakhapatnam) and Invest India both of whom conducted separate studies on the Indian Textile Engineering Industry (TEI) under the aegis of ‘Ministry of Textiles’ during the year. The KIHT conducted a ‘Technology Gap Analysis in the Indian TEI’, and Invest India published an Opportunity Paper covering the Textile Machinery Industry in India. Written in association with TMMA, it showcased India’s strengths in Textile Machinery to both global and domestic players and highlight the opportunities and advantages of investing in the Indian TEI.

Inspired by the report’s mass appeal the industry requested the association to work with Invest India again to bring out segment specific papers that would enable both the MHI and MoT to bring out suitable policies/ schemes for the industry.

“A journey of a thousand miles begins with a single step.”

After a decade of persistent efforts, for the first time the Ministry of Textiles have recognized us as their integral part and hence we are now being considered to be a part of their new scheme.

The association is closely working in this regard with the MoT to prepare a draft for ‘Textile Technology Development Scheme (TTDS)’ that would benefit both the textile and the textile machinery industry. With a proposed budget outlay of approximately INR 16500 crores for 5 years, the draft scheme is still under deliberation. There may be a lot of iterations and additions before it could be announced after the cabinet’s approval during 2022-23.

Export and R&D Awards

It is our normal practice to present Export and R&D Awards at the Annual Session of

the Association. In this Session, we are giving Awards for Export Excellence, segment wise export performance awards and Awards for R&D for the year 2021-22. He congratulated the award winners in advance for putting in great efforts in the promotion of exports and the development made in textile engineering arena.