Birla Cellulose and Usha Yarn are collaborating to use pre- and post-consumer textile wastes to make recycled yarn, which will have more than 50 per cent textile waste.

The global textile industry is struggling to bring textile waste into the circular economy stream. 50 per cent of the industry worldwide has yet to take action despite the discussion around the severity of the issue. Only less than 1 per cent of the textile waste is currently recycled. According to recent data from the Circular Fashion Index (CFI), Global Fashion brands are failing to transition towards a more circular and sustainable economy.

Owing to this, Birla Cellulose, the pulp and fibre business of the Aditya Birla Group and a leading sustainability-focused Man-Made Cellulosic Fibres (MMCF) producer, has announced a strategic partnership with Usha Yarn, a leading company in manufacturing and supply of sustainable recycled yarn.

Birla Cellulose and Usha Yarn are collaborating to use pre- and post-consumer textile wastes to make recycled yarn, which will have more than 50 per cent textile waste. The recycled yarn will be a blend of chemically recycled textile waste and mechanically recycled textile waste with the lowest energy, water, and chemical consumption.

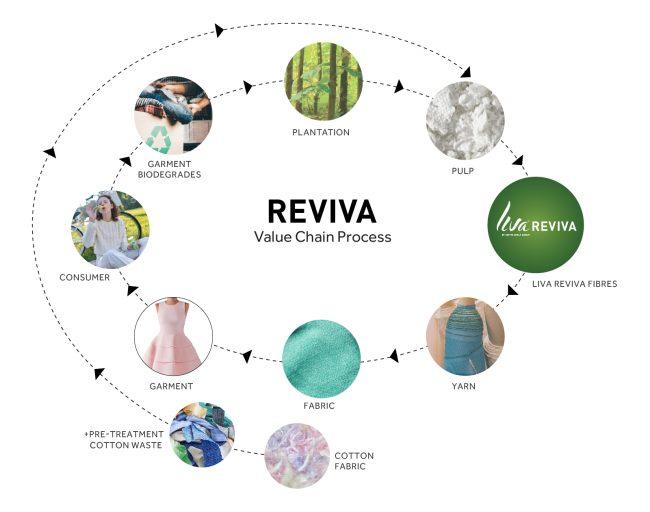

Based on their sustainable principles of responsible sourcing and responsible manufacturing, Birla Cellulose has developed chemically recycled Reviva fibre, a man-made cellulosic fibre (MMCF) that has 30 per cent textile pre-and post-consumer waste and 70 per cent wood pulp from FSC-certified forests.

As a commitment to circular fashion, Reviva operates with a unique “reverse logistics” chain for procuring textile waste, creating significant value addition.

Usha Yarns, too, over the years, has developed expertise in collecting and processing post-industrial textile wastes to mechanically recycled fibre. It has also initiated a pilot program for post-consumer garment waste as a recycling partner.

Usha Yarns regards the highest quality as an essential core value and is constantly working to ensure that you will always get the best in regenerated yarns. It has its own in-house research, quality control, and the most modern production facilities to ensure consistent global standards of high quality that you expect and deserve for every product. Moreover, they have a track record of consistently delivering large lots of flawlessly coloured regenerated yarns to produce knitted and woven garments acceptable as per global standards.

ManMohan Singh, Chief Marketing Officer, said, “Partnership with Usha Yarn is in line with Birla Cellulose’s commitment to supplying 100000 tonne of recycled fibre by 2024 and continuously innovate our offerings for recycle products by collaborating with best-in-class partners like Usha Yarn and help in providing highest quality recycled yarn to Brands.”

Anurag Gupta, Managing Director of Usha Yarn, says, “Brands are looking at new innovative sustainable yarn that has higher recycled content from textile wastes meeting Global Recycle Standard criteria and simultaneously provides the best performance when converted to garments. Our partnership with Grasim Industries will provide the necessary solution for brands backed by strong sustainability and circular credentials.”