Researchers from Washington State University developed a novel fiber blending the flexibility of cotton with the conductivity of polyaniline, a polymer. This marked a new step towards the advanced textile. In “Carbohydrate Polymers,” it has been detailed that this innovative polymer is able to create wearable e-textiles for applications like health monitoring and hazardous exposure detection.

The innovative material combines cotton’s flexibility with the conductivity of a polymer, called poly aniline. Poly aniline also showed an acceptable range of flexibiliy which is more enough to combine with cotton to develop a new fiber.

This single strand of fiber developed at Washington State University (WSU) by the researchers has both the flexibility of cotton and the electric conductivity of a polymer, called polyaniline.

The WSU researchers tested the fibers with a system that showed two results. It was able to power an LED light and another that sensed ammonia gas, detailing their findings in the journal Carbohydrate Polymers.So, it can be admitted that the newly developed material showed good potential for production of wearable e-textiles.

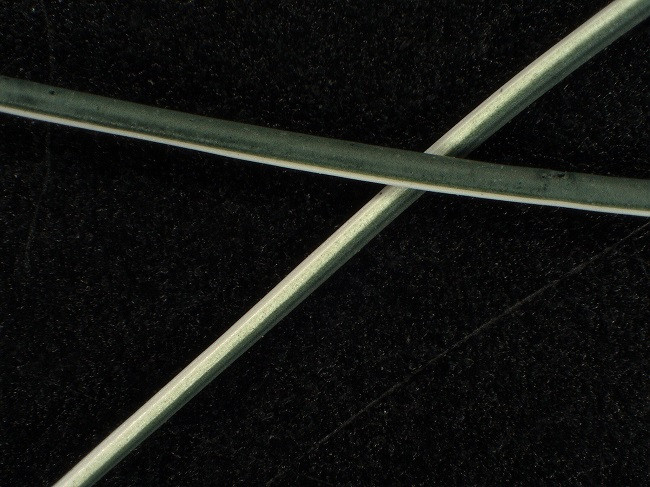

A microscopic image of the newly developed fibers showing their side-by-side mix where one side is cotton and the other contains the polyanaline polymer that can carry an electric current. Credit: Washington State University

“We have one fiber in two sections: one section is the conventional cotton: flexible and strong enough for everyday use, and the other side is the conductive material,” said Hang Liu, WSU textile researcher and the study’s corresponding author. “The cotton can support the conductive material which can provide the needed function.”

Advanced applications in Wearable Technology

In this era of technological advancement, the idea is to merge sensor patches made of this special fiber with flexible circuits. These patches could be attached to uniforms used by firefighters, soldiers or workers who handle chemicals for the detection of hazardous exposure of different explosives. The applications can be extended to health monitoring or exercise shirts.

“We have some smart wearables, like smartwatches, that can track your movement and human vital signs, but we hope that in the near future your everyday clothing will be able to do these functions as well,” said Liu. “Fashion is not just color and style, as a lot of people think about it: fashion is science.”

Technical Challenges and Solutions

The study conducted by the WSU team left a remarkable result by overcoming the challenges of mixing the conductive polymer called polyaniline with cotton cellulose.

Polymers are substances with very large molecules that have repeating patterns. In this case, the researchers used polyaniline, also known as PANI, a synthetic polymer with conductive properties already used in applications such as printed circuit board manufacturing.

While intrinsically conductive, polyaniline is quite brittle and by itself, cannot be made into a fiber for textiles. To solve this, the WSU researchers dissolved cotton cellulose from recycled t-shirts into a solution and the conductive polymer into another separate solution. These two solutions were then merged together side-by-side, and the material was extruded to make one fiber.

Washington State University textile researcher Hang Liu views a a microscopic image of the newly developed fibers showing their side-by-side mix where one side is cotton and the other contains the polyanaline polymer that can carry an electric current where electrons can flow through it. Credit: Dean Hare, Washington State University

By applying this process of mixturing two different substances, molecules from these different materials showed good interfacial bonding and stayed together through stretching and bending forming a new fiber.

Achieving the right mixture at the interface of cotton cellulose and polyaniline was a perfect balance, Liu said.

“We wanted these two solutions to work so that when the cotton and the conductive polymer contact each other they mix to a certain degree to kind of glue together, but we didn’t want them to mix too much, otherwise the conductivity would be reduced,” she said.

Reference: “A novel structural design of cellulose-based conductive composite fibers for wearable e-textiles” by Wangcheng Liu, Hang Liu, Zihui Zhao, Dan Liang, Wei-Hong Zhong and Jinwen Zhang, 18 August 2023, Carbohydrate Polymers.

Source: Credit: SciTechDaily.com