At the Dhakatex exhibition in Dhaka, Bangladesh, you will find the Saurer experts at stand 251 in hall 8. We look forward to meeting our customers and informing them about our future-oriented solutions in the areas of energy saving, sustainability, digitalisation, and automation. Together with our customers, we want to transform the spinning industry towards a circular economy and save valuable resources. Every watt we can save in the production process counts for our planet. That is why we offer a wide range of new machines and retrofit solutions to save energy in the spinning and twisting process.

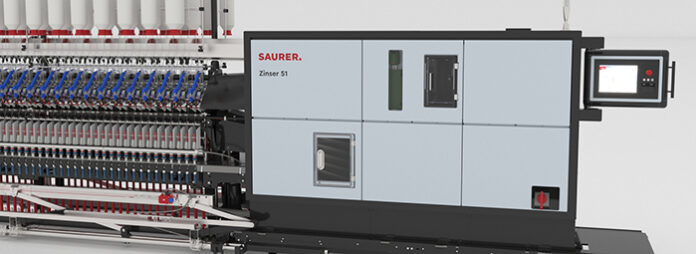

The brand-new Zinser 51 ring spinning machine series is offered as a ring-spinning or as a compact-spinning machine and sets new standards for sustainable spinning, maximum economy, optimised user-friendliness, and flexible automation solutions in ring spinning. High-end components such as the Texparts Eshape spindle and Spinnfinity, ideal for high-speed spinning, enable top speeds of up to 30,000 rpm and save up to 6% energy at the same time. To produce high-quality compact yarns, the new Zinser 51 can be equipped with the reliable compact units Impact FX and Impact FX pro.

The Saurer experts on the booth will welcome you to discuss the latest innovations of the all-new product portfolio presented last year at ITMA Milano and ITMA Asia. With its focus on automation, digitalisation, and ergonomics, the new Autocard SC7 assists spinning mills to obtain more production and higher quality with less labour.

The ring-spinning portfolio comprises the Zinser 51, the ZI 72XL compact-spinning machine, and the ZI 451 for worsted spinning. Our rotor spinning portfolio has been upgraded to process even the shortest fibres with the Autocoro 11 in the Recycling Xtreme version and the semi-automatic rotor spinning machine BD 8 is now offering a doffer as an option. The Autoairo air-spinning machine from Saurer sets new benchmarks for productivity, automation and efficiency for economical air spinning and is now processing cotton.

The Twisting portfolio includes intelligent and economical twisting and cabling machines for staple fibres, tire cord, carpet, glass filament and industrial yarns. The advanced spindle and drive design of the CompactTwister offers low power consumption and short doffing times combined with a low yarn breakage rate. Balloon limiters, energy-saving spindles, optimised drives, and many other features on Saurer’s twisting and cabling machines result in significant energy savings.

With the Texparts product line Saurer offers high-quality components for the textile industry including drafting systems and spindles, spinning rings and travellers, as well as bearings for ring-spinning and rotor-spinning, winders, and twisters. The Texparts components ensure excellent yarn quality, maximum productivity and with some products also energy savings.

Sustainability also implies longer product life. SUN-Service Unlimited offers solutions for a long and sustainable life of Saurer spinning machines as well as upgrade kits for processing recycled fibres. Additionally, Saurer provides solutions to improve the energy efficiency of your current machinery, because every watt we can save counts for our planet.