Smartex, a pioneering hardware-based software company, is proud to introduce Smartex LOOP, an innovative fabric-roll level traceability tool. This groundbreaking solution represents a significant advancement in Smartex’s mission to provide cutting-edge tools for the Modern Textile Factory. Smartex LOOP will be officially showcased at ITMA Milan, alongside several other upgrades for their valued production partners.

Smartex LOOP: Fabric-Roll Level Traceability and Data-Led Communication

Building upon the success of Smartex CORE, their AI-enabled automated quality control product, Smartex LOOP enables suppliers to take advantage of fabric-roll level data collection and revolutionize supply chain communication, as well as directly address the call from fashion brands for better supply chain data, marking a new era of transparency and collaboration. “Smartex LOOP future-proofs businesses by providing foundations for better data collection and communication, enabling them to meet the rising demand for transparency and accountability in the textile industry while improving operational efficiency,” says Gilberto Loureiro, CEO of Smartex.ai.

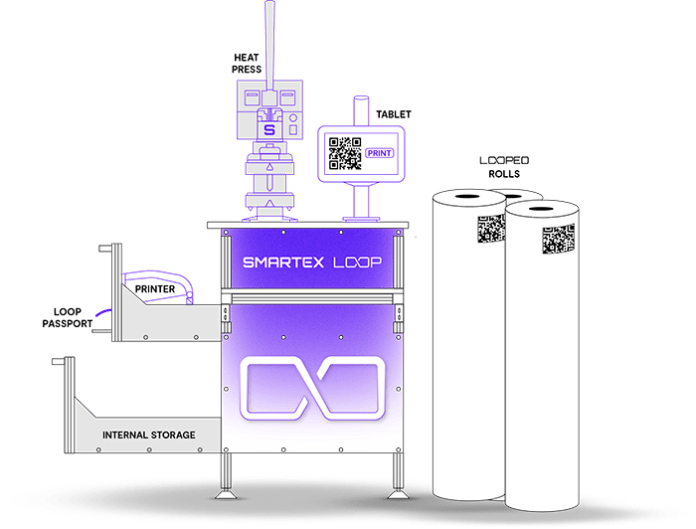

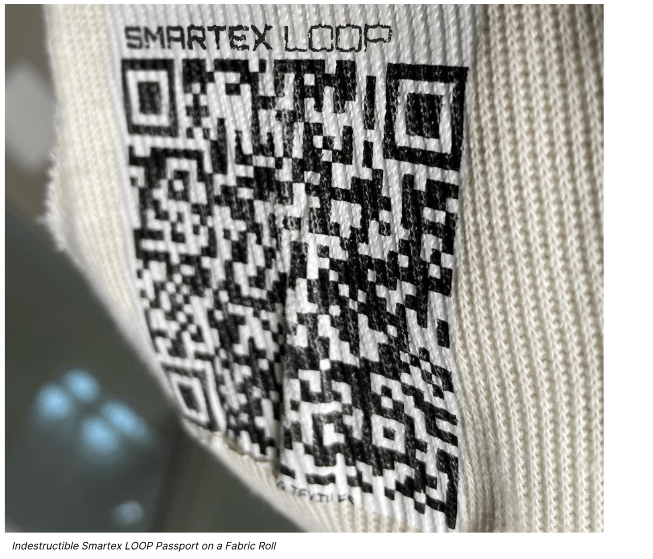

With Smartex LOOP, users can quickly scan any fabric roll’s LOOP Passport – or review all of their rolls on the Smartex Platform via their desktop or mobile – and instantly access a wealth of information about that fabric roll’s production history and quality. This powerful tool equips textile manufacturers with the means to elevate product value, increase productivity, and stay ahead of the dynamic industry landscape.

Smartex LOOP allows factories to pinpoint fabric roll issues, identifying the exact machine, worker, or yarn supplier involved. This unprecedented visibility enhances quality alignment and transparency between knitting facilities and dye house partners, fostering trust, reducing waste, and minimizing delays.

Furthermore, in the event of supply chain disputes, Smartex LOOP provides irrefutable evidence of product quality through a digital roll map, effectively avoiding time-consuming and costly litigation with upstream and downstream customers.

The benefits of Smartex LOOP extend beyond quality control. It offers vital evidence for verified wastage reduction, inventory tracking, and Tier 2 production locations, enabling fashion brands to meet the mounting demands of legislation, investors, and consumers for improved supply chain data.

Carlos Rocha, Industrial Director of Impetus Group, affirms, “We can now understand the root causes for defects occurring during our manufacturing process. By consulting LOOP, I can gather the required information to collaborate with other parties and enhance our production quality.”

Experience the future of textile traceability with Smartex LOOP, which eliminates the need for laborious manual data collection and communication.

Additional Upgrades: Smartex CORE Systems Leave No Machines Behind

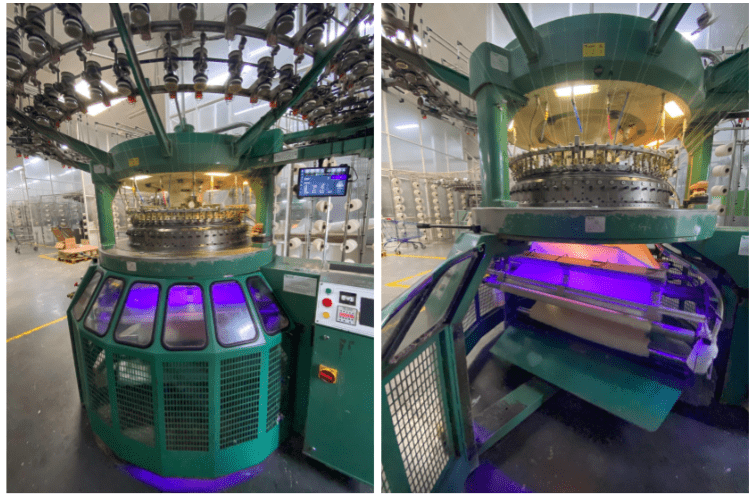

Smartex CORE, the foundation of the Smartex System, is now compatible with all circular knitting machines, including tubular machines.

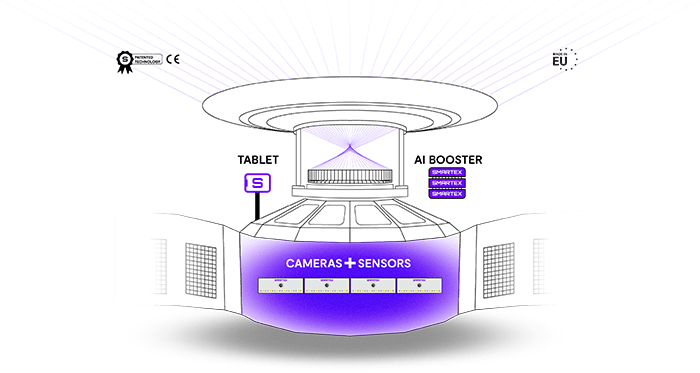

Smartex CORE facilitates automated quality control, enhancing productivity, margins, and waste reduction by eliminating roll rejections. Leveraging advanced artificial intelligence and European hardware, Smartex CORE detects and prevents defects during fabric production, addressing production issues at their source.

By expanding compatibility to include tubular circular knitting machines, Smartex ensures that all their existing and future customers can guarantee quality and optimize production with Smartex CORE.

Automate Quality Control with Automatic Roll Grading

Presenting Automatic Roll Grading at ITMA, Smartex introduces an additional tool for the Modern Textile Factory. This feature enables objective and automatic grading of all fabric rolls, departing from the subjective and sample-based approach currently prevalent in the textile industry. Leveraging Smartex CORE’s advanced camera and light system, the Smartex Platform analyzes captured photos to provide consistent and accurate grading.

Factories can customize their quality thresholds, gaining deeper insights into production and machine performance while maintaining consistent quality standards. Seamless communication of fabric roll quality across the supply chain is facilitated by integrating Automatic Roll Grading with Smartex LOOP.

On top of their recently announced AI Boost Tool and Factory System Integrations, Smartex is proud to present its Tools for the Modern Textile Factory at ITMA.

Discover Smartex’s Tools for the Modern Textile Factory

Interested individuals and organizations are invited to visit Smartex’s main booth (H4-E103) at ITMA Milan. Additionally, Smartex will exhibit at three additional booths: Terrot (H4-E104), Norsel (H4-C306), and Unitex (H2-D204). Whether you want to drop by or schedule a visit, please get in touch with sales@smartex.ai or find out more by visiting their website.

Smartex’s substantial presence at ITMA Milan underscores the company’s commitment to driving innovation and shaping the future of the textile industry.